Mobile Robotics in Cleanrooms: Challenges and Innovation Needs

Presented by: Martin Søndergaard Andersen, Project Manager, Novo Nordisk A/S

Edited by: Ben Norris

The pharmaceutical industry is experiencing a complete technological overhaul. As different sections become digitised and automated, each aspect will be linked together — from production line to patient. Increasingly, this extends to data on how often patients are taking their medicine, and data on how well the body responds to that medicine. However, how can the process of manufacture be refined and automated without a loss of flexibility? For Martin Søndergaard Andersen, Project Manager at Novo Nordisk A/S, robots in cleanrooms represent a key pillar in the future of pharmaceutical production.

What are the Applications of Mobile Robotics in Cleanrooms?

Andersen’s presentation at our Mobile Pharmaceutical Robotics 2022: In-Person event opened with some background on Novo Nordisk’s investment in healthcare provision. “The main thing is that we help people with a lot of things in their day-to-day lives,” said Andersen. He explained that Novo Nordisk produces and supplies nearly 50% of the world’s insulin, and that the company supports more than 35 million people daily living with diabetes in terms of manufacturing their medicine. “I think we should continue on that path and make sure those 35 million people get the best medicine they can.”

- Read: Oxford Global's R&D Key 40 Stories

- From Space Robotics to the Mobile Lab Robotics of the Future

- Why Should Researchers use AI to Analyse Healthcare Data?

Addressing the question of why mobile robots are important for production, he outlined Novo Nordisk’s aseptic production line. “If a production line breaks down then we have to have an intervention, we have to have something in there that facilitates that,” Andersen said. In addition, the contamination and maintenance of surfaces is a factor for consideration. “There has to be cleaning of the walls, floors, everything. Maybe even of the robot itself.” Andersen also clarified the need for disinfection as well as cleaning, stressing that these were two different processes. “We’ll have to tackle that somehow,” he said. “That’s what we’ve done before, that’s what we’re really good at.”

Evaluating Approaches in Mobile Robotics Design

The approach opted for by Andersen and his colleagues at Novo Nordisk was to refine their development process for mobile robotics in cleanrooms. Optimising for the highest possible specifications enables a translatable approach which can be adapted to other scenarios with a lower requirement threshold. “In the past, we’ve purchased some existing mobile robot or some existing equipment off the market that’s not fit for production, and we focus very much on the application side of it,” said Andersen. “But as soon as you want to integrate that into the pharmaceutical process, we hit this wall of requirements which means we have to redesign completely.”

As Andersen explained, going back to square one and purchasing some different equipment to customise is a time-consuming process in and of itself. “If you want to take every process we have in pharmaceutical production and automate it this way, it will be very slow and very expensive.” However, another option presented itself. “We thought, let’s start this the other way around — let’s start with this wall of requirements that’s always the limiting factor.” To tackle this approach, Andersen and his team started with the requirements expected by authorities when designing a mobile robot. “All of these applications have a common denominator,” he said. “It’s the mobile robot base.”

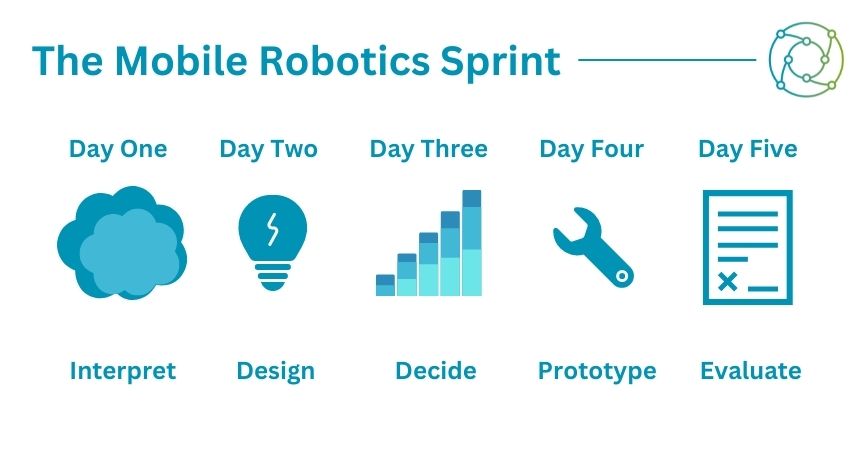

The Mobile Robotics Design Sprint

The subsequent process that Andersen and his colleagues followed was a design sprint — a five-day block where the team cleared their schedule for a week to build a prototype robot and validate it for suitability. One of the primary focuses in construction was cleaning, which is a significant manual procedure that gets carried out every day in cleanrooms. “The reason that we clean is because we have people involved in production,” said Andersen. “We have this paradox that keeps going into a spiral, where we have people that need to clean but we need to clean because of people. It’s a very iterative process.”

Andersen explained that Novo Nordisk used the sprint to construct a mobile robot that tackled all the critical areas for design. “Wheels we thought were important, as they’re the only point of contact for the floor,” he explained. “That means they touch the entire facility, and that means we have to clean them with some frequency. If there is contamination on the floor, we don’t want the mobile robot to drive over that contamination and spread it to the entire facility.” The solution was to have the wheels somewhere easy to access for either cleaning or routine removal and replacement.

A key design aspect was the robot’s shell, which had to be optimised for cleaning. “We were thinking that a sphere is a nice object to clean,” said Andersen. “It’s a bit hard to put together a mobile robot that’s a sphere, but the idea was to have smooth surfaces with no hidden cavities where microorganisms can hide.” He added that another focus was ensuring the body had as few holes as possible to reduce the risk of any contaminant entering the robot body. “We had two holes for the wheels, and then one interface stand — we put an application on top so we can seal it and it’s easy to clean.”

The Mobile Robot of the Future

The prototype developed by Andersen and his team was a success. He explained that the end goal was to develop a cleanroom robot that can be implemented everywhere. “We don’t want this to be a Novo Nordisk product,” said Andersen. “We want this to be a pharmaceutical industry product. It’s easier for us to go to the authorities if it’s something we as an industry want rather than something we just want as a company.” Additionally, if there is evident demand for mobile robotics in cleanrooms across the industry as a whole, robotics supply companies are more likely to be interested in supporting the development of such a product.

“We want this to be a pharmaceutical industry product... it's easier for us to go to the authorities if it's something we want as an industry.”

Andersen closed his presentation by emphasising the importance of taking a more holistic approach to product design for mobile robotics in cleanrooms. “By doing that, we let the requirements dictate product design.” He added that this was, as he saw it, the most important thing he could contribute to the pharmaceutical industry if the move towards digitisation and automation is set to continue as it has in recent years. “This is something we have to tackle, and this is something we have to tackle together.”

Want to read more about current trends in and around mobile robotics in pharma? Head over to our PharmaTec portal to get the latest insights from the industry’s best and brightest. If you’d like to check out our upcoming Pharmaceutical Mobile Robotics Congress, visit our event website to download an agenda or register your interest.