Sustainability in Pharmaceutical Manufacture and Healthcare Provision

Sustainability in pharmaceutical manufacture is becoming more pertinent as a focus for research and investment almost by the day.

In 2009, the total carbon footprint associated with the US healthcare industry was estimated at half a billion tons.

Worldwide, the healthcare sector now contributes to 4.4% of global emissions – this is two gigatons of CO2, greater than the total produced by aviation or by shipping.

If healthcare was a country, its carbon footprint would make it the fifth-largest emitter globally; it would also need to slash its emissions by roughly two-thirds in the next two years to stay in line with goals outlined in the 2015 Paris agreement.

While the global healthcare market is expected to reach USD$ 83.4bn by 2024, growth in prescription medicines is projected to climb to USD$ 1,562.1bn by 2026.

Meanwhile, environmental issues such as air pollution and extreme temperatures are all associated with health impacts, and so contribute to healthcare costs (an annual estimated USD$ 800m in the US alone), creating a vicious circle.

Ways to improve sustainability in pharmaceutical manufacture include scaling renewable energy by introducing energy efficiency measures.

Some of these involve changing employee behaviours, updating outdated infrastructure, and improving renewable energy sourcing.

Supply chains are an essential part of this, particularly with the manufacturing of substrates and (active pharmaceutical ingredients APIs often requiring the transport of materials from off-site.

Cutting the Carbon Footprint of Manufacturing

A particularly salient point is the manufacture of APIs, as the ingredients used in small-molecule drugs largely rely on chemicals derived from petroleum.

The chemical synthesis of raw materials and solvents also involves many energy-intensive steps, and the amount of carbon involved in the creation of these molecules is often not calculated.

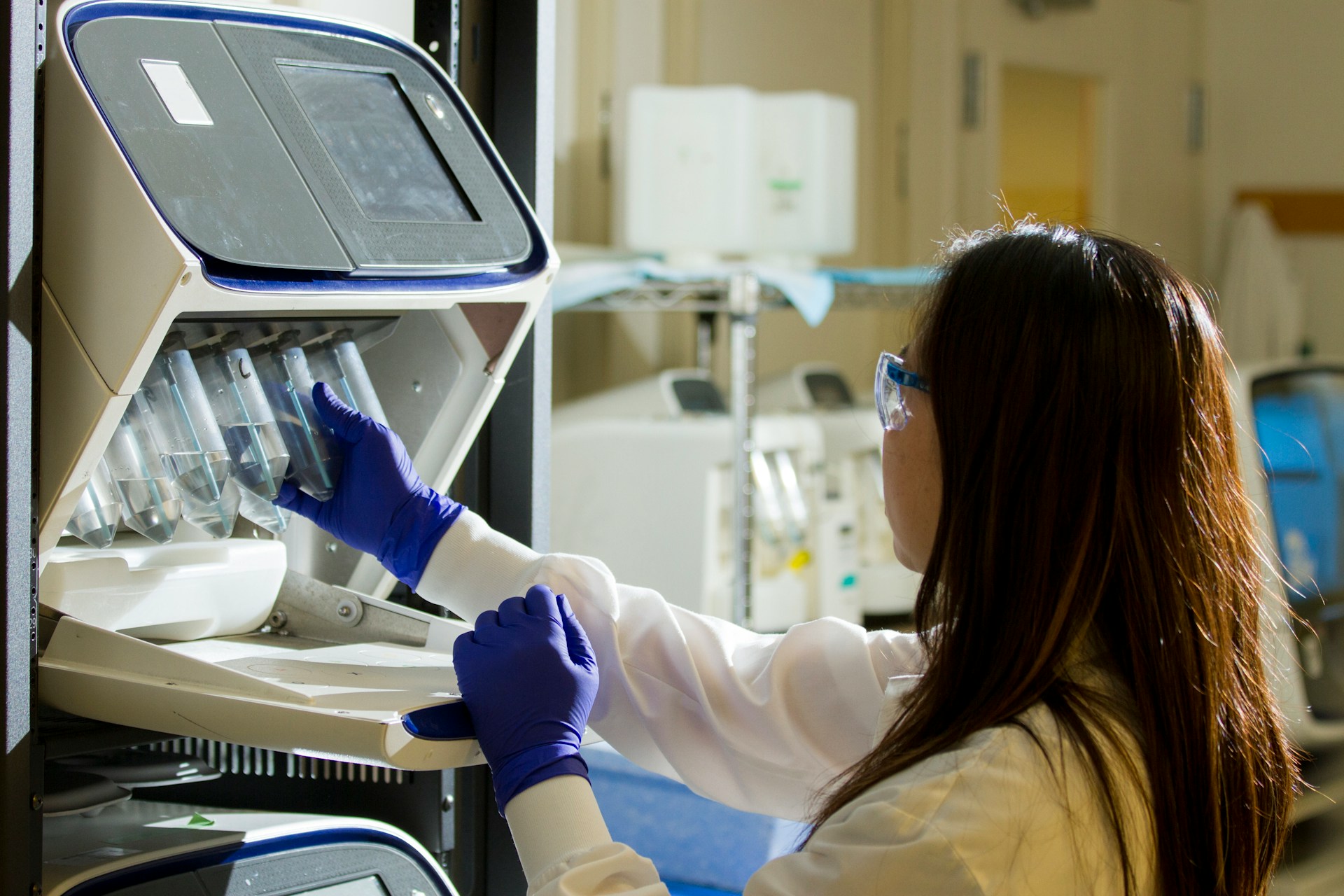

One of the most effective ways of reducing the carbon emissions associated with drug production is to adopt continuous manufacturing – an efficient alternative to branch manufacturing that combines multiple separate production stages into one single, continuous production line.

As one example, the US Biotech Amgen opened a $200m biomanufacturing plant incorporating continuous production methods in Singapore.

This plant produces 69% less carbon emissions than an equivalent batch production and manufacturing line.

Sanofi established a continuous manufacturing plant in Massachusetts in 2019, which it hopes will generate 80% less carbon than the company’s first-generation facility.

Merck has also recently completed a USD $25m refurbishment of its cell culture media plant in Kansas, USA: the expansion included a roof upgrade to a sun-reflecting material, along with the optimisation of its air-conditioning units.

A Move Towards Renewables in Pharma Manufacturing

Moving away from fossil fuels and shifting towards greener energy will be crucial to pharma and biotech companies looking to meaningfully curb their carbon emissions in the next few years.

Some key considerations include the sourcing of electrical energy from renewables – in 2021, Catalent announced that 97% of its electricity came from renewable resources such as wind, solar, hydroelectric, and biomass.

Another loss-making aspect is cold chain shipping, wherein temperature sensitive products such as insulin and some vaccines are transported at controlled temperatures which do not compromise their efficacy or safety.

The refrigerated vehicles used to transport these products require additional energy to power the cooling systems used to keep products at a controlled temperature.

An easy win for reducing the carbon emissions associated with cold-chain shipping involves investing in greener fuels and energy sources for transport vehicles.

This has the dual result of increasing energy and cost efficiency while minimising the environmental impact of cold-store supply chains.

Alternatively, some companies have been investigating the feasibility of developing products which can be stored at higher temperatures, mitigating the need for resource-intensive refrigeration during transport.

Overall, there are a variety of approaches pharma companies can take to reduce their emissions across each stage of the manufacturing and supply journey and improve sustainability in pharmaceutical manufacture.

To learn more about our upcoming Biologics UK conference, visit our event website to download an agenda and register your interest.

Related Resources